Key words: Graphite Electrodes, Refractory Material(brick, Mix), Copper Mould Tube, Mill Roll

+86 186 4091 3888

Key words: Graphite Electrodes, Refractory Material(brick, Mix), Copper Mould Tube, Mill Roll

+86 186 4091 3888

The Sinometal's possesses domestic advanced production line ofrefractories used in metallurgy industry; more than 160 sets of extensive manufacturing facilities; and more than 30 sets of checkout equipment. The company's annual output of magnesia carbon brick, alumina magnesia carbon brick and aluminiumcarbide brick and so on is 70,000 tons.

Product description

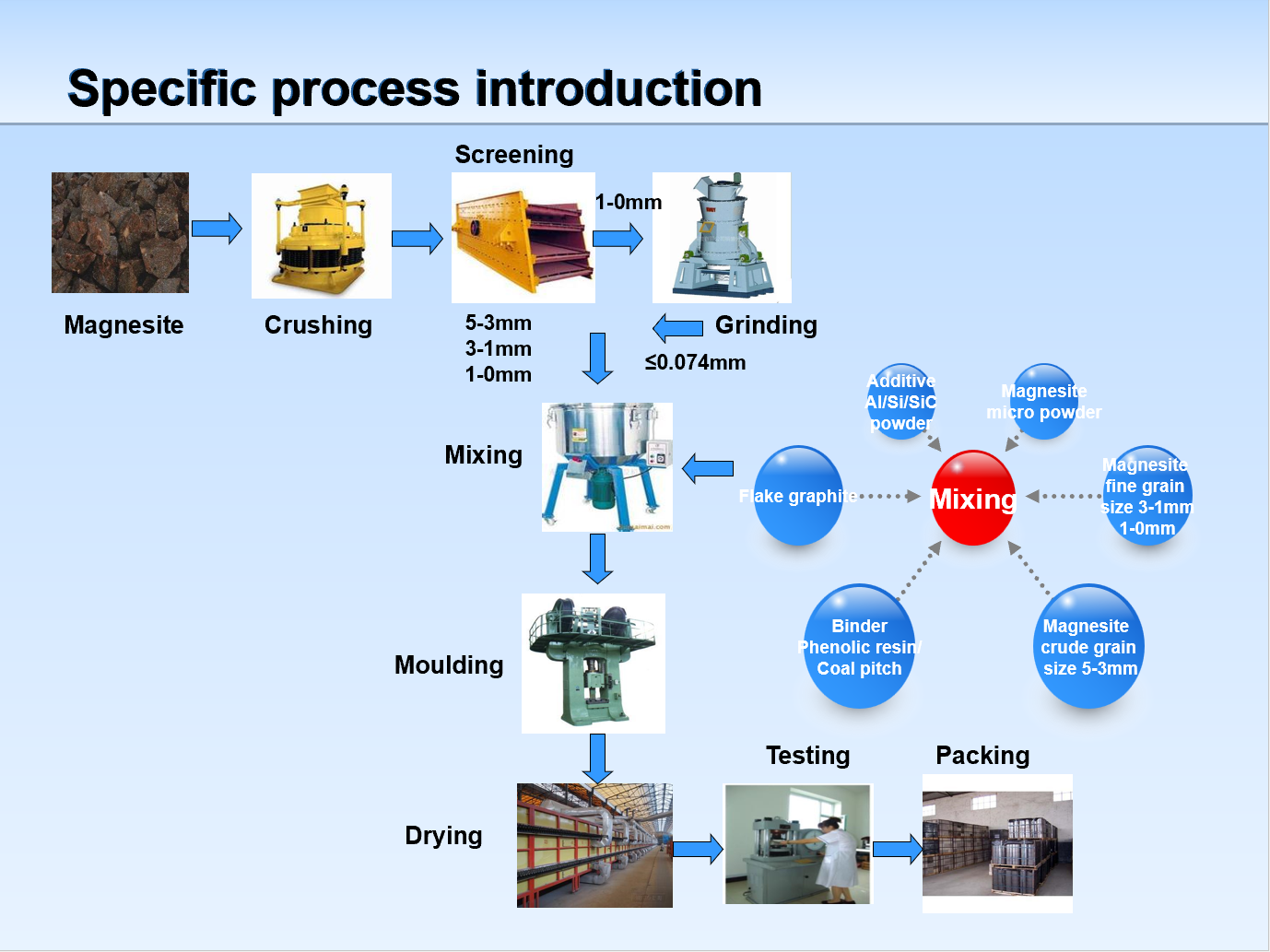

Magnesite Carbon brick is a kind of basic refractory which is made from magnesite, graphite as raw material, resin as binder, with high pressure moulding and low temperature treatment.

◆ As one kind of compound refractories, heat resistant bricks make magnesite good slag erosion risistance and graphite high thermal conductivity and low dilatability mixed together.

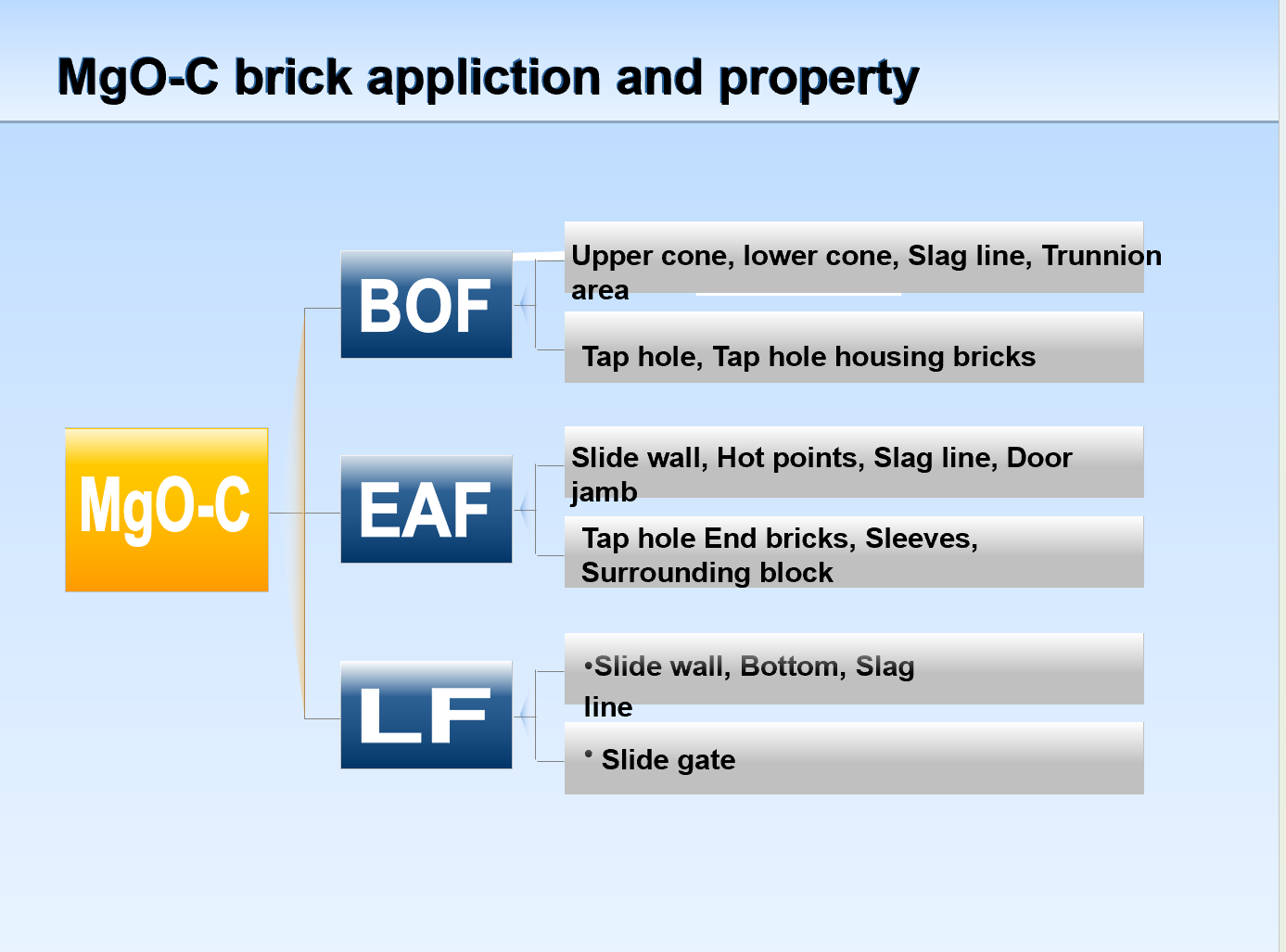

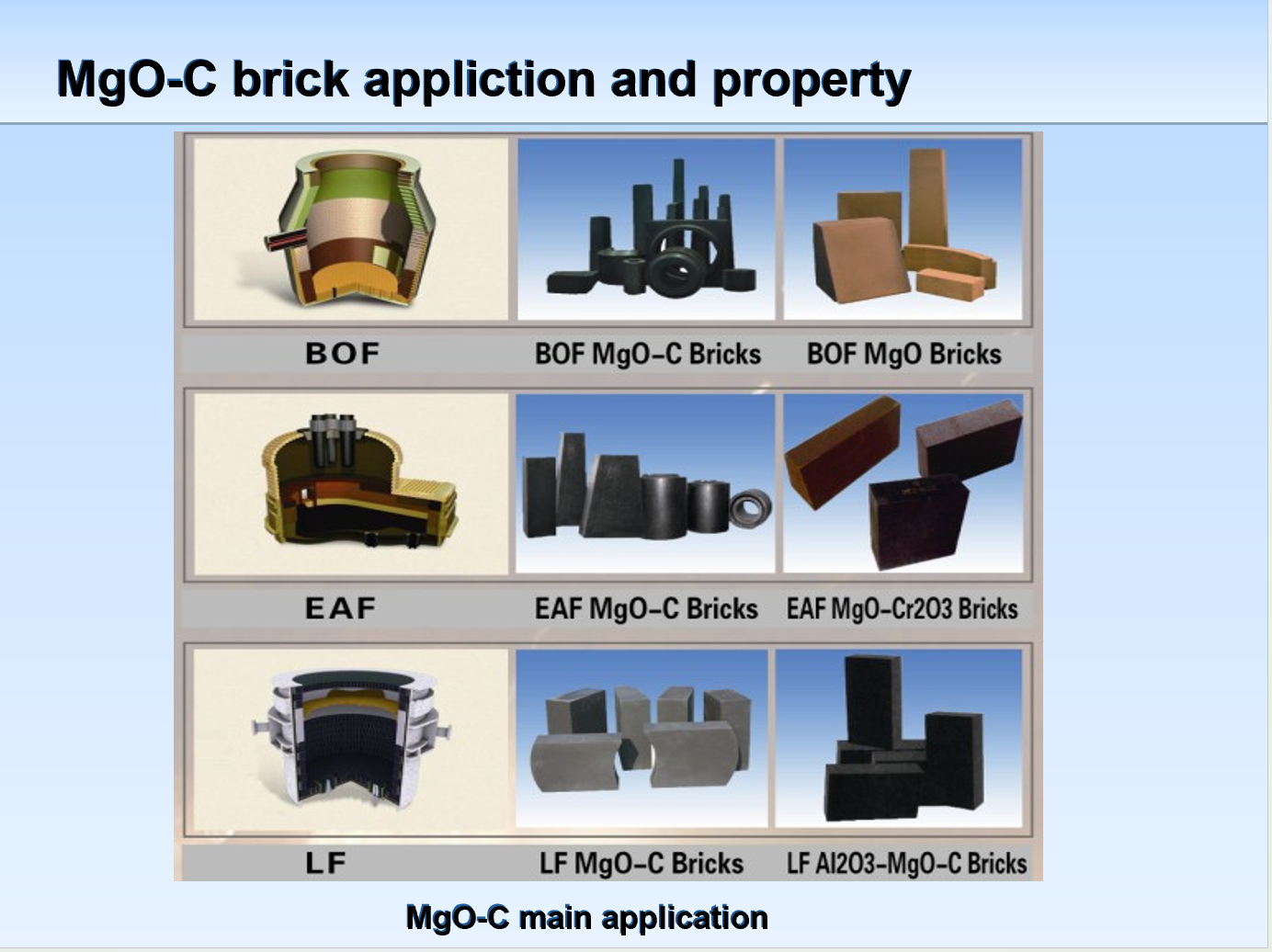

◆ Mg-C brick has features of high refractoriness, good thermal shock resistance, erosion resistance, and has good performance in I&S industry, including BOF, EAF, LF.

◆ Refractory fire bricks have the advantages of good performance, long life and low cost.

Alumina Magnesia Carbon brick

Alumina Magnesia Carbon brick has same production process, the main raw materials are fused alumina or bauxite, so it has better strength and refractoriness under load, but the slag resistance is not as good as magnesia carbon bricks.

Company Advantage

◆ Quality advantages: All magnesia bricks of the company are in accordance with national standard as well as the enterprise's standard, and has got ISO9001 Quality Management System Certification and ISO14001 Environment Management System Certification.

◆ Scientific and technical advantages: The company invested a large sum of money to built the building of engineering technology center which covers an area of 5,000 square meters in 2012.The company's capability of scientific. And long supply experience as a professional mgo c brick supplier, Sinometal can make sure to give customers total solutions.

Quality Guarantee

Five aspects guarentee the product quality.

1. Our plant has passed ISO 9001:2008 QMS, and strictly executed the relevant standards.

2. Puesue "Quality is the enterprise life" of this principle.

3. Set up Technical Inspection Center which is the magnesite material base of Liaoning Province.

4. Mature production process and technical support, build up closed cooperation with famous research institutes.

5. A wealth of supply experience for large scale I&S company at home and abroad.

6. Professional before-sale and after-sale service.

MgO-C bricks are composite materials based on MgO and C, bonded with high carbon-containing resin and some metallic powders as anti-oxidants to protect the carbon durability. These bricks show excellent resistance to thermal shock and slag corrosion at elevated temperatures, making them ideal for use in high-quality steel alloy making processes.

Magnesia carbon bricks applications

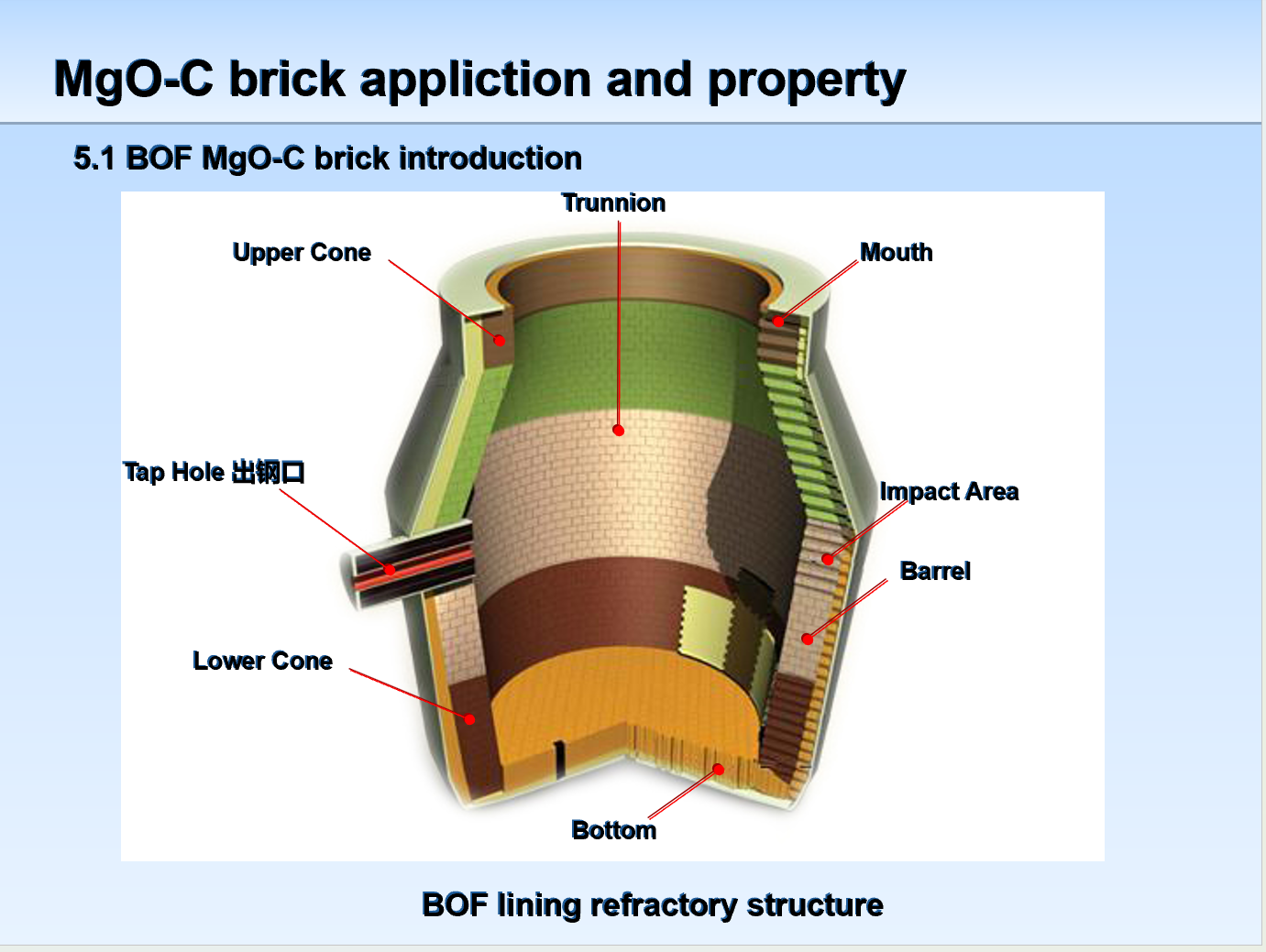

◆ Basic Oxygen Furnace Linings

MgO-C bricks are extensively used in the linings of basic oxygen furnaces due to their high refractoriness and resistance to thermal shock and slag corrosion. This ensures the longevity and reliability of the furnace lining, reducing maintenance costs and downtime.

◆ Reformer Furnace Linings

In reformer furnaces, MgO-C bricks provide the necessary thermal stability and resistance to chemical attack, ensuring efficient and consistent operation. The low thermal expansion and good resistance against thermal shock make them suitable for these high-temperature applications.

◆ Electric Arc Furnaces

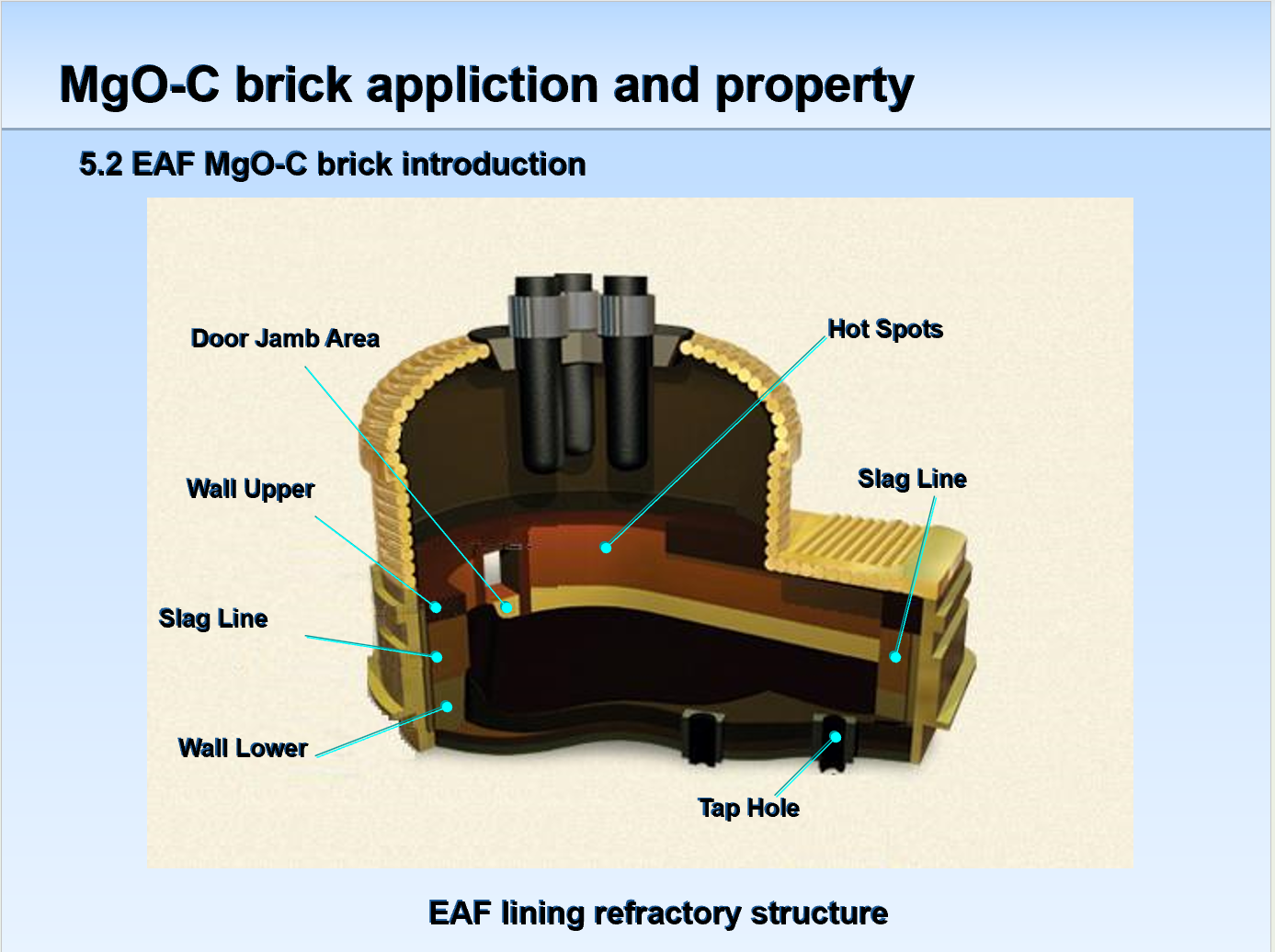

MgO-C bricks are used in electric arc furnaces to withstand the extreme temperatures and thermal shocks encountered during the steelmaking process. Their high refractoriness and low wettability of slag help maintain the integrity of the furnace lining.

◆ Ladles

For ladle refining furnaces, MgO-C bricks are essential for maintaining the quality of the steel during the refining process. They provide excellent resistance to slag corrosion and thermal shock, ensuring that the ladle can withstand multiple cycles of use without degradation.

Navigation

Tel:: +86 186 4091 3888

Fax: +86 411 3962 5877

Mobile: +86 186 4091 3888

E-mail: jack@sncarbon.cn

Skype: graphite.sinometal@outlook.com

QQ: 695993847

Address: Zhongshan District, Dalian City,116001. China.